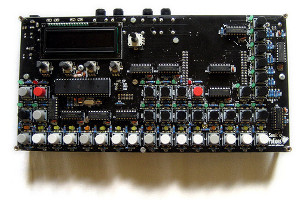

LXR kit assembly Kit assembly PDF (4.6MB)

Kit assembly PDF (4.6MB) Kit assembly french PDF (4.6MB) BOM (google spreadsheet) Schematic front PDF (440kb) Schematic CPU PDF (271kb) |

LXR acrylic enclosure assembly Acrylic enclosure PDF (580kb)

Acrylic enclosure PDF (580kb)

|

LXR metal enclosure assembly Metal enclosure PDF (1.5MB)

Metal enclosure PDF (1.5MB)

|

LXR trigger IO assembly Trigger IO PDF (2.1MB)

Trigger IO PDF (2.1MB) Schematic PDF (103kb) BOM (google spreadsheet) |